Quality

Excellence You Can Count On

Our commitment to quality testing is not just about compliance; it’s about guaranteeing excellence. We verify that our conduit performs reliably under various conditions, ensuring optimal installation and long-term performance. Whether it’s for high-speed data networks, advanced telecommunications, or critical infrastructure projects, our conduit is engineered to excel.

Testing of Raw Materials

By rigorously testing our raw materials, we proactively prevent defects and production issues, ensuring that our final products consistently meet or exceed industry standards. Through meticulous material selection and stringent quality control measures, we guarantee the durability and reliability of every conduit we manufacture.

Operations & Processes

Our consistent setup helps us maintain the highest quality product and ensures that we continually meet precise dimensions and tolerances. This means less material waste and speeds the production process, which lowers costs for you, our customer.

Extruders

These machines heat and melt the HDPE pellets, then force the molten plastic through a die to form the conduit shape. The extruder is critical for achieving the desired diameter and wall thickness.

Cooling Tanks

After extrusion, the conduit is cooled in water or air-cooling tanks to solidify and maintain its shape. The cooling process is essential for ensuring the conduit’s dimensional stability.

Pullers

These devices draw the conduit through the cooling tanks and onto winding equipment. They ensure consistent diameter and prevent deformation during cooling.

Continuous Improvement

At Conduit Direct Group, we place immense value on the feedback we receive from our customers. Your insights into product performance and any issues encountered are vital to our continuous improvement efforts. We actively listen to your experiences to ensure that our conduits not only meet but exceed your expectations.

Your Feedback

Your insights drive our innovation and quality enhancements, allowing us to better meet your expectations and provide solutions that consistently deliver superior performance.

Our Promise

This ongoing commitment to improvement ensures that our conduits evolve in response to real-world performance and emerging needs.

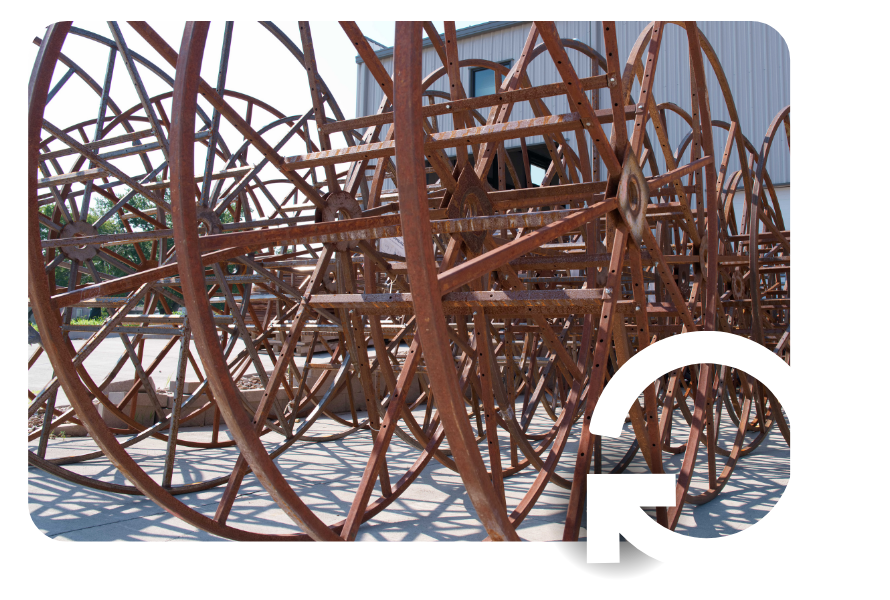

REEL RETURN PROGRAM

Locate reels that meet the Acceptable Guidelines and return them for cash. Reusing steel reels is environmentally friendly and cleans up the work area. Reels in good condition can be sent back to Conduit Direct Group for reuse.