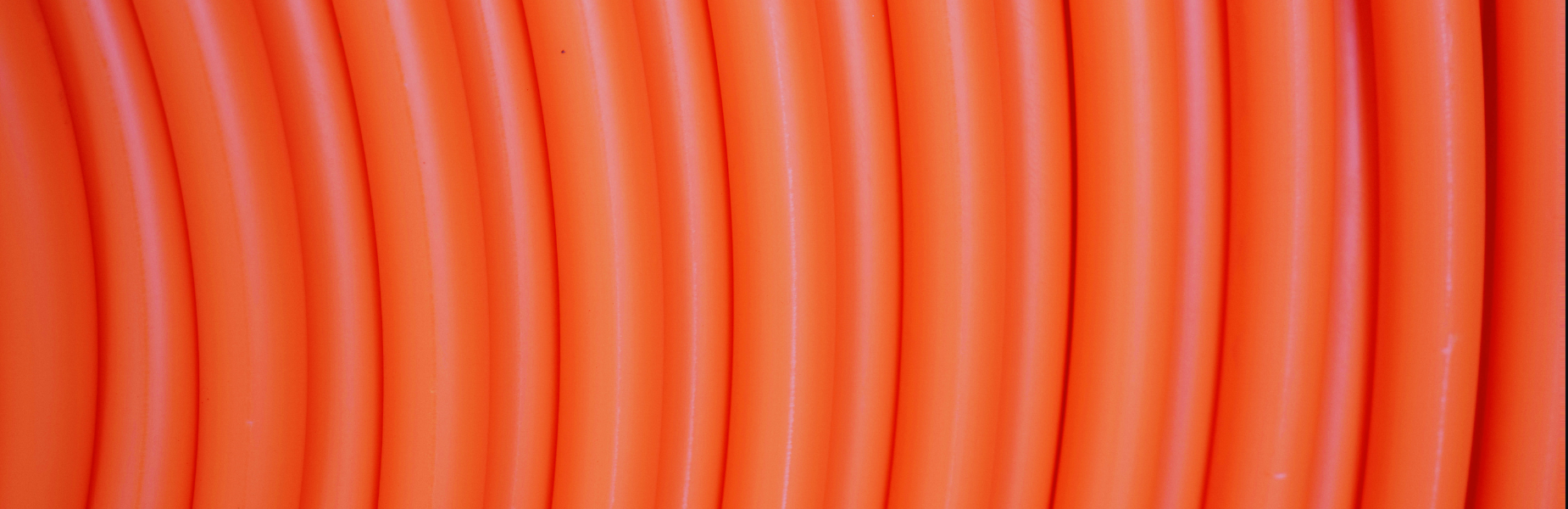

HDPE Conduit

Why choose us for your HDPE Pipe?

Conduit Direct Group is a leading manufacturer of high-quality HDPE conduit engineered to protect and house fiber optic cables, power cables, and other essential data or communication transmission lines. Our HDPE conduit is manufactured to strict industry standards, offering superior flexibility, durability, and resistance to corrosion, chemicals, and harsh environmental conditions. Whether used for underground directional drilling, direct burial, or aerial installations, Conduit Direct Group’s HDPE conduit ensures exceptional performance and long-term protection for your critical cable infrastructure.

Competitive Pricing

By being our own manufacturer we cut on costs that most suppliers can’t. Then we pass that savings to our customers.

Customized Orders

Since we manufacture in house we offer more customized options with faster turn around times. See all our available options below.

Short Turn-Around Time

Our team goes the extra mile to ensure that you get your conduit when you need it. We understand the importance or turn-around times on the job-site.

Options for HDPE Conduit

Our conduit is engineered to withstand harsh environmental conditions, including UV radiation, water, and extreme temperatures. Its durable construction resists abrasion and scrapes, ensuring long-term reliability. See the options available for custom orders that we offer below.

Conduit Types

Smooth Wall

Interally Ribbed

AVAILABLE SIZES

.75″, 1″, 1.25″, 1.5″, 2.0″

Wall Types

SDR9, SDR 11, SDR 13.5, SCH40

Optional Add Ons

Pre-Installed Pull Tape – 1/2” 1250 lb

Or call (319) 450-1911 to talk to one of our experts!

HDPE Conduit Use Cases

HDPE conduit is a reliable and durable solution for protecting critical fiber optic cables, power lines, and other communication infrastructure. Its superior strength, flexibility, and resistance to environmental factors such as moisture, chemicals, and temperature changes make it the ideal choice for a wide range of industries and applications.

Telecom

Our HDPE conduit solutions provide telecom providers with durable, industry-compliant pathways for installing fiber optic and copper cables. HDPE conduit is flexible and easy to install using directional drilling or direct burial, helping telecom companies meet project deadlines efficiently while future-proofing their networks to handle increasing data traffic demands.

Internet Service Providers

For internet service providers, HDPE conduit ensures secure and long-lasting protection for fiber optic cables and communication lines. Its high resistance to cracking, corrosion, and ground movement preserves cable integrity, ensuring uninterrupted service and reducing maintenance costs over time.

Power & Electrical Utilities

HDPE conduit is also widely used in power distribution to house electrical cables safely underground. Its non-conductive, corrosion-resistant properties make it ideal for protecting electrical infrastructure against moisture, chemicals, and soil shifts.

Municipal & Infrastructure Projects

Municipalities use HDPE conduit for street lighting, traffic signals, and public utilities. Its lightweight nature and long reel lengths make installation quick and cost-effective for large-scale infrastructure projects.

Key Benefits of HDPE Conduit Across Industries

- Superior flexibility for easy installation in tight or curved pathways

- Excellent resistance to chemicals, corrosion, and abrasion

- Long service life, often exceeding 50 years

- Lightweight for easier transportation and handling

- Compatible with trenchless installation methods like horizontal directional drilling

Frequently Asked Questions

Answers to everything you need to know about our HDPE conduit offerings. If you don’t see the answer to your questions, contact us and we’ll get you an answer!

What is HDPE Conduit?

HDPE conduit is a type of electrical and communications conduit made from high-density polyethylene. It is used to protect and route cables or wiring in underground and above-ground installations. Known for its flexibility, durability, and resistance to corrosion, HDPE conduit is lightweight yet strong, making it ideal for directional drilling, plowing, and direct burial applications. It can withstand harsh environmental conditions without cracking or breaking, ensuring long-lasting protection for fiber optic, power, and telecom cables.

What does HDPE stand for?

HDPE stands for High-Density Polyethylene.

What are the cost advantages of using HDPE Pipe and Conduit?

Reduced Installation Costs:

- Easy bending for trenchless installation

- Fewer joints needed for longer lines

- Strong, leak-proof heat-fused joint

Long-Term Savings:

- 50+ year lifespan reduces replacement costs

- Superior impact resistance, especially in cold weather

- Lower cost and weight compared to metal pipes

Why get a quote for HDPE pricing?

HDPE prices can fluctuate due to factors like raw material costs, supply and demand, and transportation expenses. To ensure accurate pricing, a quote is necessary to consider your specific project requirements.

HDPE Conduit Sizing and Innerduct Capacity

- NEC Guidelines: The National Electric Code provides guidelines for the number of conductors allowed in a conduit based on its diameter.

- Casing Pipe Fill: The maximum recommended fill for a casing pipe is 70%. However, the optimal fill percentage depends on the run’s length and complexity.

What does SDR stand for?

SDR, or Standard Dimension Ratio, is a measure of pipe wall thickness. A higher SDR indicates a thinner wall. The appropriate SDR for a project depends on factors like bore length, diameter, soil conditions, and ASTM standards.

REEL RETURN PROGRAM

Locate reels that meet the Acceptable Guidelines and return them for cash. Reusing steel reels is environmentally friendly and cleans up the work area. Reels in good condition can be sent back to Conduit Direct Group for reuse.